RoTao’s IPASS(Independent Propulsion/braking, Axle adjustment, Steering, and Suspension) wheel units are designed for an EV(electric vehicle) skateboard platform. It is a mechanism of a highly modularized, low-unsprung-mass, and electrically controlled general wheel unit for building future vehicles.

Attaching motors directly to the wheels and attaching wheel units to a flat chassis seems like an obvious choice if only for its mechanical simplicity. Without any conventional transmission and mechanical linkages, the motors can develop torque onto wheels directly and individually. The modularized design offers flexibility and cost-efficiency. But, some recent designs with hub motors(in-wheel motors) will add greater unsprung mass. In general, higher unsprung mass makes a bumpier and noisier ride and can lead to wheel control issues. It also reduces the service life of the suspension springs and makes them more likely to break due to the work required to maintain the vehicle’s traction. Thus, many automobile designers consider direct-drive motors to be an inherently problematic approach.

Traction adaptively optimized control (TAO) is a mechanism in which the central controller of a vehicle sends commands to the wheels individually according to the potential road and traffic conditions of each wheel. The commands include operating the propulsion, braking, axle adjustment, steering, and suspension to achieve dynamic reactions, coordinately and collaboratively. The combination of these operations achieves optimized performance and features.

There is good demand in various applications for which only IPASS designs can provide distinct competitive advantages. All the difficulties and problems in designing a good IPASS system have previously blinded most vehicle manufacturers to its benefits. Now it is time to bring low-unsprung-mass, traction-adaptively-optimized control, and highly modularized near-wheel motors with independent propulsion, braking, steering, and especially axle adjustment.

The purpose of the design is to achieve the traction-adaptively-optimization (TAO) control which includes but not limited as the following: 1) better road surface gripping and ride quality by lower unsprung mass; 2) safer, quicker, and sharper turning ability – transformative turning; 3) adaptive obstacle avoidance; 4) a list of new, unique, and advanced vehicle motion features, such as parallel driving or parking, dynamic track width adjustment, torque vectoring, stepless kneeling, real all-wheel drive (AWD), and pizza braking. Additionally, it allows a compact vehicle meet the RoTao elevated track standard width by extending its axles.

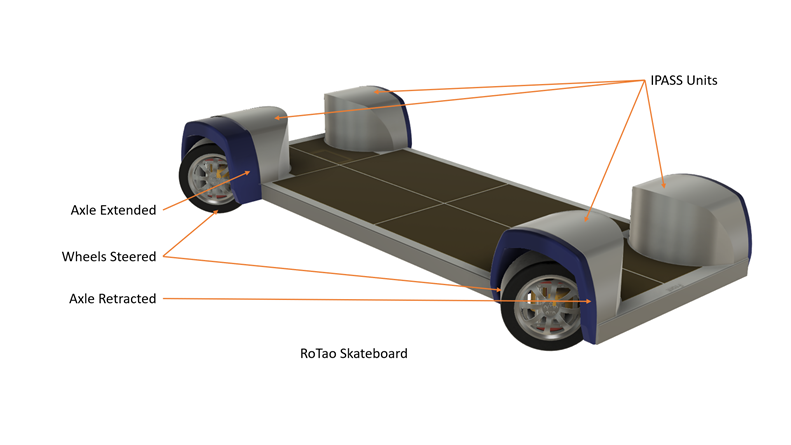

The mechanism comprises at least the following components. An axle adjustment dynamically controls the track width. It allows for outward extension or inward retraction of the wheel axle via an electric linear actuator. Since there is no physical axle connecting each pair of wheels, the independent axles work together to form a virtual axle and track width of the vehicle. The independent propulsion system, powered by an electric motor near and perpendicular to the wheel shaft, controls the wheel’s forward and backward motion through a spline shaft, a bevel gear reducer, and planetary gear reducers. The wheel unit’s low-profile steering system includes a pair of thrust bearings and turning gears and a motor. The design of the steering system results in an extremely low profile, it requires no additional height above the wheel. Each wheel unit also has an independent suspension system located inside the corresponding wheel hub. The suspension uses a dampening mechanism, which uses hydraulic cylinders and springs to absorb the shock from vertical movement when driving on uneven surfaces.

The aforementioned electric motors are connected to the main battery by wires; the main battery transmits electrical power to the motors instantaneously based on the driver’s command and input. By substituting some of the mechanical components with wires, the weight of the vehicle can be reduced, and the vehicle is easier to control. Furthermore, all wheel units work coordinately ensures the versatile control demand. Since the wheel units are independent, each independent system operates at a different rate. Examples may include, but are not limited to: (1) how much the electric linear actuator pushes or pulls each wheel fender for track width adjustment; (2) the degree that each unit rotate during steering; (3) how much the propulsion motor creates the rotational force, (4) the height of each suspension when the vehicle body tilts during a sharp maneuver (i.e. transformative turning), and etc.

The figure in this article illustrates a EV’s skateboard chassis equipped with 4 IPASS units. For heavy duty vehicles, 6, 8 or more units may used to build a multi-axle chassis. Thanks to the all-wheel steerable capability, it makes the steering less of friction, more precise and lower turning radius. As variety of requirements, one or more features of the IPASS units can be omitted. A large vehicle may not need the axle extension feature, in case of lowing the cost, a vehicle may not need all-wheel drive feature, all-wheel steerable feature or active suspension feature.

RoTao’s IPASS approach offers multiple customer benefits including cost efficiency, vehicle design freedom, faster development time, increased maneuverability, ADAS compatibility, reduced maintenance costs, and compliance with RoTao’s elevated track standard.